Moulin à ciment, Moulin pour matière première

Moulin à ciment, Moulin pour matière première

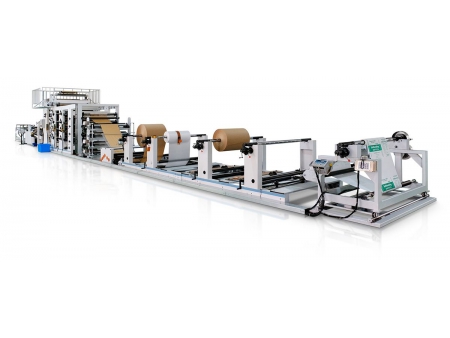

The end cap and central quill shaft of Hongxing cement mill and raw material mill is made using monobloc casting. Meanwhile, the large end cap and the material discharging system adopt streamlined structure, which effectively reduces air resistance and increases the effective volume. This guarantees easy and smooth material discharging and improves the production capacity of our cement mill and raw material mill.

1. Raw material mill

1. The raw material mill adopts single-cylinder structure, and different types of lining plate are available for use in different grinding stage. This helps improve production efficiency greatly.

2. Negative pressure inside the grinding mill can effectively avoid powder-leakage conditions.

3. With hot drying air and interior heat preservation system, the raw material mill offers a drying capacity from 6% to 8%.

4. DCS connection is available, which can satisfy users’ demand on central control of the mill.

2. Cement mill

The cement mill is a key piece of grinding equipment designed for reducing crushed materials into powders in building material production, metallurgy, chemicals and mining industries. It is originally designed for use in production lines for cement, but now it is also used in production lines for powders like silicates, refractory material, fertilizer, new type of building material, glass ceramics and more. Meanwhile, the cement mill is also suitable for ore dressing of both ferrous and non ferrous metals. Both dry and wet type grinding are allowable.

Technical specifications

Given below are the specifications of cement mill.

Specification (m) | Style | Drive type | Speed reducer | Motor power (kw) | Production capacity (t/h) | Weight (t) | |

Model | Speed ratio | ||||||

φ1.83×7 | Open circuit system | Edge drive | ZD60 | 4.5 | 245 | 6.5-8 | 41 |

φ2.2×7.5 | Closed circuit system | Edge drive | ZD70 | 5 | 380 | 8-10 | 58 |

φ2.2×11 | Open circuit system | Center drive | D110 | 35.5 | 630 | 12-13 | 104.6 |

φ2.2×13 | Open circuit system | Center drive | D110 | 35.5 | 630 | 16-18 | 114 |

φ2.4×13 | Open circuit system | Center drive | D110 | 35.5 | 800 | 20-23 | 130.6 |

φ2.6×13 | Open circuit system | Center drive | MFY100 | 19.5 | 1000 | 28-32 | 158 |

φ3×9 | Closed circuit system | Edge drive | D125 | 41.2 | 1000 | 28-36.5 | 167 |

φ3×11 | Closed circuit system | Center drive | D140 | 42.8 | 1250 | 36-47 | 180 |

φ3.2×13 | Open circuit system | Center drive | D140 | 36.5 | 1600 | 45-50 | 225 |

φ3.8×13 | Open circuit system | Center drive | MFY250 | 16.5 | 2500 | 60-62 | 320 |

φ4.2×13 | Open circuit system | Center drive | JQS3550 | 15.6 | 3530 | 85-87 | 380 |

φ4.6×14 | Closed circuit system | Center drive | JSI160-C |

| 4200 | 120-135 | 485 |

Given below are the specifications of raw material mill.

Specification (m) | Style | Drive type | Speed reducer | Motor power (kw) | Production capacity (t/h) | Weight (t) | |

Model | Speed ratio | ||||||

φ1.5×5.7 | Open circuit system | Edge drive | ZD40 | 3.55 | 130 | 4.5-6 | 24.7 |

φ1.83×6.4 | Open circuit system | Edge drive | ZD60 | 4.5 | 210 | 7.5-15 | 36 |

φ2.2×6.5 | Closed circuit system | Edge drive | ZD70 | 5 | 380 | 14-26 | 52.8 |

φ2.2×13 | Open circuit system | Center drive | D110 | 35.5 | 630 | 29-34 | 114 |

φ2.4×6 | Closed circuit system | Edge drive | 2HD-700-10ⅡJ | 5.53 | 380 | 15-38 | 72 |

φ2.4×10 | Closed circuit system | Edge drive | 2D80-4-Ⅱ | 6.435 | 570 | 25-45 | 118 |

φ2.4×13 | Open circuit system | Center drive | D110 | 35.5 | 800 | 40-50 | 130.6 |

φ2.6×13 | Open circuit system | Center drive | MFY100 | 19.5 | 1000 | 43-54 | 158 |

φ3×9 | Closed circuit system | Center drive | D125 | 41.2 | 1000 | 32-68 | 167 |

φ3.2×9 | Closed circuit system | Edge drive | MBY900 | 7.1 | 1250 | 62-65 | 195 |

φ3.8×7.5 | Closed circuit system | Edge drive | JDX900 | 5.6 | 1600 | 80 | 233 |

φ4.6×10 3.5 | Closed circuit system | Center drive | JQS3550 | 15.1 | 3550 | 190 | 415 |

φ4.6×10.5 3.5 | Closed circuit system | Center drive | JQS3550 | 15.1 | 3550 | 210 | 476 |

Hongxing is a cement mill, raw material mill manufacturer in

Mèches de réparation Tubeless / Cordes de réparation des pneus sans chambre à air / Mèches de réparation des pneus sans chambre à air

tirerepair-products.fr

Mèches de réparation Tubeless / Cordes de réparation des pneus sans chambre à air / Mèches de réparation des pneus sans chambre à air

tirerepair-products.fr