Variateur de fréquence couplé au ventilateur de dépoussiérage dans l'atelier de broyage

Variateur de fréquence couplé au ventilateur de dépoussiérage dans l'atelier de broyage

2009-12-15 13:29:30

Résumé : cet article est principalement tourné vers la technologie de production du ciment, ainsi que l’application du variateur de fréquence moyenne tension VFD fabriqué par Beijing Leader & Harvest Electric Technologies Co., Ltd. couplé avec le ventilateur de collecte de poussière dans l’atelier de broyage Pingyin de la cimenterie de Jinan Shanshui. Il élabore également une analyse économique et d’autres innovations techniques pertinentes. L’installation du variateur de fréquence moyenne tension VFD de Leader & Harvest pour économie d’énergie, procurent les caractéristiques suivantes, investissement économique, haute efficience et fonctionnement stable.

Mots clés : variateur de fréquence moyenne tension VFD, usine de broyage centrale, économie d’énergie.

I Preface

There is a cement production line of annual 1000000t in Jinan Shanshui Group. At first, dust collecting fan was constant speed running. Its air flow was controlled by damper. Because of variety of output and product kinds, it needs different air flow to satisfy process requirement. If controlled by damper, it is not only bad in adjusting precision but also wasting energy. In order to improve process technology and reduce power consumption, Shanshui Group decided to innovate with technology of variable frequency.

After lots of inspections and demonstrations, the plant chose HARSVERT-A06/055 VFD produced by Beijing Leader &Harvest Electric Technologies Co., Ltd.

1. Motor drives millstones to rotate via reducer. Materials fall in center of millstones from feed opening and move to edge by centrifugal force. After grinding, comminuted materials leave millstones and are brought to isolator by high-speed air flow. After isolating, coarse powder returns millstones and is milled again. Thin powder leaves millstones following air flow and is collected by dust collecting system.

Speed of fan is decided by process technology (output and fineness).

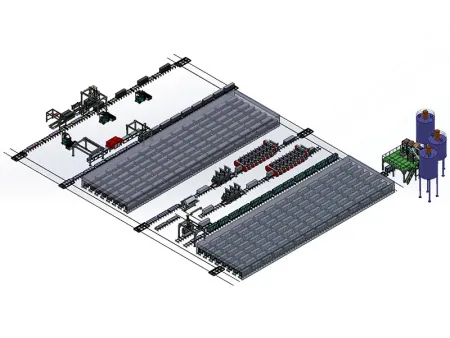

2. Main equipments of grinding system

Name | Model | Capacity | Motor power(kW) |

Roll squeezer | RP120-80 | Diameter 1200mm, Effective width 899mm | 2×500 kW |

Tubing mill | ∮4.2×11.5 | 120t/h | 2800 kW |

Powder concentrator | XWS40 | 150 t/h | 220 kW |

Bag type dust collector | LPM2X70 | 157000m3/h | |

Exhaust fan | R6-2X40No15.57 | 160000 m3/h, 7300Pa | 450 kW |

Technics process

II Control scheme of dust collection fan

1. Main circuit

Principle: VFD drives a motor. Input of VFD connects to 6kV power source and output connects to motor. QF1 is high voltage breaker in site. In order to protect VFD, VFD interlocks with QF1. only when VFD control system is normal, can QF1 close.

2. Control circuit

According to user requirement, VFD can adjust air pressure as per pressure signal and also interlink with air gate.

There are local control and remote control in controller cabinet of VFD. User can choose any one. VFD supports protocol of MODBUS, PROFIBUS, TCP/IP and hard wire to implement remote control. In this project, VFD connects to DCS through hard wire. Namely, DCS gives command of start, stop, given frequency to VFD, VFD feeds back DCS digital signals of “ready”, “running”, “alarm”, “fault” and analogue signal of “motor speed” and “motor curret”.

3. VFD data

NO | Item | Unit | Parameter | Remark |

1 | Standard | Q/CP BLH003-2004 | ||

2 | Model | HARSVERT-A06/055 | ||

3 | Manufacturer | Leader&Harvest | ||

4 | Technology | Cell-cascade, high-high | ||

5 | Motor | Asynchronous squirrel cage motor | ||

6 | Input voltage range | kV | 6kV±15% | |

7 | Input voltage | kV | 6kV | |

8 | Input frequency range | 50Hz±10% | ||

9 | Voltage fluctuation | 15%~-35% | ||

10 | VFD efficiency | >0.98 | ||

11 | Harmonic | Input current<4%,output current<2% | ||

12 | Free fault time | H | 20000h | |

13 | Power factor | >0.95(>20%load) | ||

14 | Control mode | Multi level sin PWM | ||

15 | Control power | 220V±10 Produits relatifs

Variateur de fréquence moyenne tension pour application dans le ventilateur de dépoussiérage de l'aciérie de HangzhouCommentaires

Autres Produits

Plus récents

Plus

Autres Produits

Vidéo

|