Application du variateur de fréquence dans le ventilateur de dépoussiérage de la raffinerie d'Agang Steel

Application du variateur de fréquence dans le ventilateur de dépoussiérage de la raffinerie d'Agang Steel

2009-12-15 16:28:33

Résumé : techniques d’intégration du four électrique, cette page introduit le schéma de contrôle du variateur de fréquence dans le ventilateur de dépoussiérage et conclu que l’économie d’énergie du variateur de fréquence VFD dans le ventilateur de dépoussiérage est considérable.

Mots clés : four électrique, techniques de production, variateur de fréquence haute tension, économie d’énergie.

Agang Steel Plant is subsidiary company of Xilin Steel&Iron Group, locating in Acheng city 22km away southeast to Haerbin. Its main product is steel using in light rail and mining. XY30 type steel which is high performance with super low temperature has put into use for Qinghai-Tibet line as key product promoted by railway bureau.

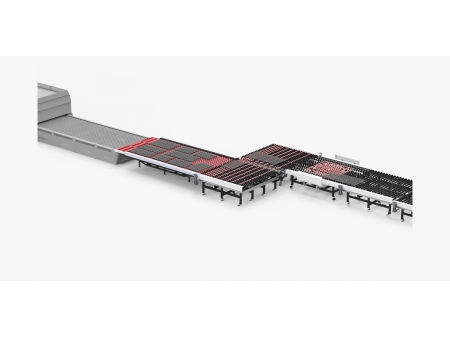

At present, the plant has 2 sets of advanced 60t super big power DC arc furnace, 2 sets of 75t LF refining furnace. Yearly steel production is 800000t. Following is technics procedure:

II. Reform reason

Power consumption of dusting system was much since it put into operation in October, 2004. In 2005, its power consumption was 21720000kW.h, power cost was 11360000yuan, and dusting consumption was 57kW.h/t, namely 30yuan/t. Electrical personnel researched kinds of methods of power saving to solve this problem. There are several ways:

1. Adjust air door of fan accroding to load changing to control current. For existing dusting system, pipe resistance is big when air door in half opening. Fan and pipe surge is serious. It brings serious wear and tear on driving parts and damages bearing, not safe for operation. So system can not run for long term in state of half opening of air door.

2. Currently, air door can only full open or full close. When electrical furnace stops for one hour or more, close the air door. The motor current lowers to 50% of rated current. Energy saving is obvious. But in the moment of switching from full open to full close, vibration of fan, pipe and workshop is big. This method can not work for long time in term of safety of building and basement.

3. When furnace load is small, particular in night, stop SA dusting fan to save energy. In this way, 6000kW.h can be saved every day. But it does not ensure standard of environmental protection. This method is not a permanent solution.

Thereby, equipment project department researched scientific method to save power. According to related information and data, high voltage variable frequency technology was considered feasible. After demonstration, plant purchased 2 sets of VFD for PA dusting fan.

III. Technics and parameters

1. Plant has 2 sets of DC arc furnace. They needs power and oxygen blowing periodically during refining procedure. In order to meet requirement of energy saving and environmental protection, PA fans are required to run in variable speed in whole refining period, high speed in oxygen blowing and low speed without oxygen blowing. In normal state, electrical furnace produces a batch of steel every 90min. These are processes of production period:

Stage a. Add waste liquid iron, 5min

Stage b. Power on and oxygen blowing, 60min

Stage c. Waite for sample, output steel, block output, 25min

Dust is less in a and c stage, fan runs in low speed. Frequency is controlled at 10~20Hz. Dust is more in b stage, fan runs in high speed. Frequency is controlled at 40~45Hz.

2. Parameters of fan and motor

Fan | motor | ||

Model | Y4-73no28F | Model | Y5603-8 |

Air flow | 520000m3/h | Rated power | 1000kW |

Air pressure | 3500Pa | Rated current | 118A |

Dusting type | pulsed jet cloth filter | Rated voltage | 6kV |

Rated speed | 742rpm | ||

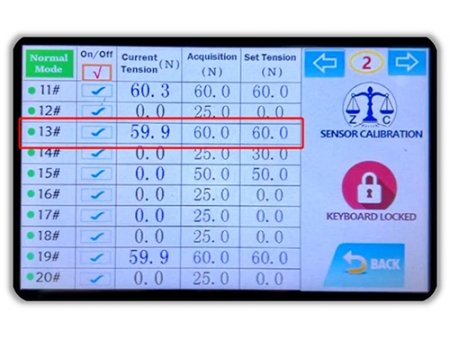

3. High voltage VFD has function of remote control and local cotrol. In local control, user can start, stop, set speed, set frequency on HMI of VFD. In remote control, user controls VFD by operation platform and upper PC in control room. User can master operation state by upper PC and controls VFD by operation platform. User can choose VFD “manual/auto” speed adjustment according to state.

IV. Control scheme

1. High voltage VFD connects to motor directly. Driving mode is “one drive one” with bypass cabinet. Switch variable frequency state to direct on line manually. Motor can start through bypass cabinet directly without VFD.

2. Set interlock between speed adjustment and steel output. Set high speed and low speed stage with manual/auto switch function. Set “manual/auto” switch and “speed stage” switch on operation platform. High voltage VFD runs in high/low speed automatically according to production state.

V. Project implementation

The company purchased Leader&Harvest VFD eventually through bidding on 27 th Aprial, 2006. HARSVERT-A06/130 VFD arrived site on 25 th June and made commissioning on 9 th August, put into operation on 10 th August.

VI. Energy saving

1. Energy saving

Power consumption of dusting fan has lowered much since VFD put into service in August, 2006. During first half year of 2006 without VFD, dusting fan consumed power 1839574kW.h every month, consumption was 47.8kW.h/t. After using VFD, from August to December, dusting fan consumed power 1360836kW.h every month, consumption was 32.28kW.h/t. We can see VFD saved 478738kW.h every month, corresponding to 253731yuan. As of 10 th February 2007, high voltage VFD has been running 6 months. 1522400yuan(USD223882) was saved. That is to say annual economic benefit is 3000000yuan (USD441176) or more.

2. Indirect benefit

a. Soft start makes start-up smooth, reduces current impact on motor, bearing and fan, prolongs equipments time.

b. High voltage VFD can control air flow according to refining process, reduce heat loss of electrical furnace. That saves energy indirectly.

3. Motor vibration is small resulted from speed lowering. Fan noise also lowers. That improves envrionment.

4. VFD adopts structure of high-high voltage source cell-cascade multi-level. Power factor reaches to 0.95. Harmonic is also lowered.

VII.Concluding remarks

From steel production process, we see high voltage VFD application in each process can gain effect of energy saving and emission reduction, such as coking, sintering, iron refining furnace, steel refining furnace, dusting fan, ventilation fan and pump.

With VFD, power consumption of dusting fan is reduced a lot in the plant. Average energy saving rate reaches to 26%. It lowers refining cost and reduces environmental pollution, brings enormous benefits for Agang Steel Plant.

Mèches de réparation Tubeless / Cordes de réparation des pneus sans chambre à air / Mèches de réparation des pneus sans chambre à air

tirerepair-products.fr

Mèches de réparation Tubeless / Cordes de réparation des pneus sans chambre à air / Mèches de réparation des pneus sans chambre à air

tirerepair-products.fr