Application du variateur de fréquence dans cimenterie

Application du variateur de fréquence dans cimenterie

2009-11-29 23:23:45

I. Introduction

Dalian Xiaoyetian Cement Plant est une société de capitaux sino-japonaise, fondée en 1989. Sa production journalière est de 4000t et sa productivité annuelle est de 1 370 000t. Dans l’usine, le moteur du ventilateur de refroidissement et du ventilateur EP (ventilateur de dépoussiérage électrique) est un moteur asynchrone à rotor bobiné. Le mode d’opération original est un mode d’opération en pleine vitesse. Le flux d’air est ajusté par la vanne d’entrée. Comme le réseau de l’usine est limité, le moteur ne peut démarrer à pleine tension. Un moteur asynchrone à rotor bobiné est nécessaire. Afin d’économiser de l’énergie et d’avoir un démarrage en douceur, l’usine a choisi un variateur de fréquence VFD pour ajuster la vitesse du moteur (juste une connexion courte avec le bobinage du rotor.)

II. Project scheme

The bypass switch cabinet of the system is a one-drive-one manual bypass system.

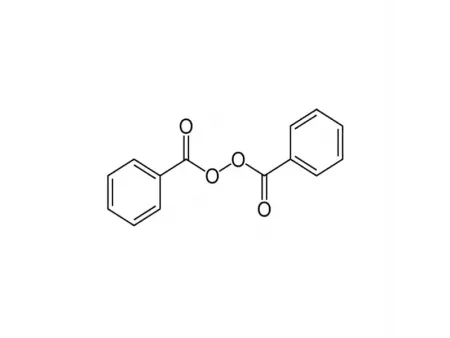

It is composed of 3 medium-voltage isolating switches QS1, QS2 and QS3 (see the following figure). QS3 and QS2 can not close at same time. They are interlock mechanically. In variable frequency state, QS1 and QS2 close and QS3 opens. In direct on line state, QS1 and QS2 open, QS3 closes.

QS1, QS2, QS3: Manual isolating switches

QF: Medium voltage vacuum circuit breaker

BPQ: VFD of HARSVERT

M: Asynchronous motor

Parameters

Motor parameters:

Model: BST-0

rated power: 330kW

rated voltage: 6kV

rated current: 42.8A

rated speed: 590rpm

Power factor:0.8

VFD parameters:

Model:Harsvert-A06/045

Input voltage:6kV

Capacity:420kVA

Rated current:45A

III.Project effect

1. Energy-saving effect

Energy-saving is considerable after using VFD. Before using VFD, inlet vane usually opens at 40% and motor runs at full speed; after using VFD, fans runs at variable speed, VFD usually runs at 31 Hz. Power loss is reduced a lot. Data are shown in following table.

Time | Adjusting mode | Input current(A) | Frequency(Hz) | Motor average power (kW) |

Before using VFD | Inlet vane | 32 | 50 | 266 |

After using VFD | VFD | 7.5 | 31 | 74 |

Before:

Motor average power=32×1.732×6×0.8=266kw

After:

Motor average power=7.5×1.732×6×0.95=74kw (note: power factor is 0.95 when VFD works)

Energy-saving rate is (266-74)/266=72.2%

Annual workday: 300days, power price: 0.5yuan/kwh

Saving cost=(266-74)×300×24×0.5=691000yuan (USD 101617)

2. Production-improving

Before | After | |

Start-up mode | With series water resistance | Soft-start |

Fan noise | big | small |

Bearing temperature-rise | high | low |

Adjusting response | quick | slow |

Maintenance period | short | long |

We can see from above table the indirect effect after modification is obvious. Because VFD usually runs at 30 Hz, motor and fan speed are low, their bearing temperature is low, noise is smaller. Operators can adjust motor speed through monitoring interface at DCS. Frequency resolution precision is 0.01Hz. Adjustment precision is high. In addition, we find that motor temperature-rise is not up but down.

IV. Conclusion

Cement plant made a success at energy-saving and production-improving after reconstruction with VFD.