Variateur de fréquence moyenne tension dans pompe de condenseur

Variateur de fréquence moyenne tension dans pompe de condenseur

2010-1-4 14:54:31

【Résumé】:Cet article se focalise sur l’application du variateur de fréquence VFD moyenne tension multi niveau à cellule en cascade fabriqué en Chine dans l’unité 2# du système de condensation d’eau de Zhangshan Power Company et fait une comparaison sur l’économie d’énergie avant et après la réforme. Les résultats montrent que l’utilisation du variateur de fréquence moyenne tension par l’équipement auxiliaire principal de la centrale est faisable, avec un retour rapide et d’autres caractéristiques. Le variateur de fréquence VFD réduit significativement la consommation.

【Mots clés】Variateur de fréquence moyenne tension pompe de condenseur Application

1.Preface

Zhang Shan power plant has two units of air-cooling system of of 300MW. VFD is manufactured by Beijing Leader&Harvest Electric Technologies Co., Ltd. Pump adopt mode of “one work, one standby”. Water level of deaerator is adjusted by damper. We have a discussion about VFD application according to the actual situation of # 2 Unit condenser Pump reform in Zhangshan Power Plant.

2.Operating Conditions

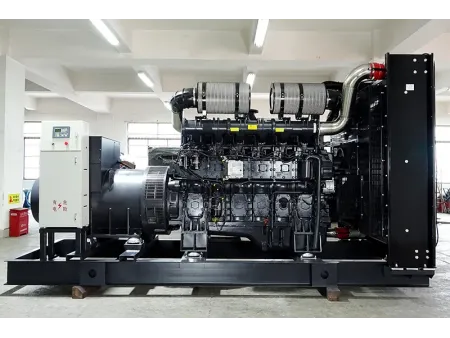

to ensure continuous and stable operation of condenser pump is an important factor of power generating units security. Condenser system is shown in following

Principle of system is shown in following

After the VFD reform, during normal operation, adjust VFD output frequency to change the speed of Condenser pump, to adjust flow and control the water level of deaerator. Following

is condenser control programe.

3.The effect of Energy-saving

(1)The power saving is remarkable in the plant

As shown in Table 1:

Unit Load(MW) | 200 | 210 | 220 | 230 | 240 | 250 | 260 | 270 | 280 | 290 | 300 |

Pump Current(Before Reform) | 81.8 | 84.2 | 85.4 | 88.0 | 90.6 | 91.1 | 93.9 | 94.5 | 95.0 | 95.8 | 98.2 |

Pump Current(After Refore) | 29.0 | 30.5 | 36.0 | 43.0 | 48.0 | 50.0 | 52.0 | 56.0 | 70.0 | 72.0 | 82.0 |

Reduce the current A | 52.8 | 53.7 | 49.4 | 45.0 | 42.6 | 41.1 | 41.9 | 38.5 | 25 | 23.8 | 16.2 |

Table 1:VFD current before and after the reform

Units | power consumption kW·h | power saving kW·h |

#1(direct on line) | 307000 | |

#2(variable frequency) | 186000 | 121000 |

Table 2:Saving Statistics

As each unit run 300 days a year, according to the power price 0.25 yuan / kWh. 605000 yuan (USD 88970) is saved.

(2)Reduce the impact current when the motor starts

Observing the load curve, we find no impact current when the VFD starts. The current rises from zero with speed increasing and never exceeds the rated current in any cases. Therefore, VFD solves the large current impact issue when the motor starts, eliminates a large starting current to the motor, significantly reduces the costs of routine maintenance. Here is starting current trend (Initial Speed: 900r/min).

(3)Extend equipment life

Using the VFD can change the motor speed along the condenser pump characteristic curve, extend the life of the bearing. Data shows that reducing condenser pump speed can prolong life of condenser pump. So cost would naturally be reduced.

(4)Reduce noise

After the reform, not only pump speed is down but also the noise dramatically lowers. Condenser pumps operating conditions have improved significantly.

4.Conclusion

The successful application of VFD on condenser system fully shows that VFD control technology has a broad application prospects and development potential with significant energy-saving effect, good system response and quality of control. It has a positive significance in improving the competition power of enterprises and reducing cost.

From the Editor:

For VFD reform project in Zhang Shan Power Plant 2 × 300MW units, Beijing Leader-harvest electric technologies Co., Ltd makes full electrical system design, DCS logic design, system commissioning, construction and other technical services. Leader Harvest provides a comprehensive and effective technical support services for the implementation of the project to achieve energy-saving. Leader Harvest VFD optimizs the system operation process, protects system security, improves energy efficiency and other economic benefits.

Mèches de réparation Tubeless / Cordes de réparation des pneus sans chambre à air / Mèches de réparation des pneus sans chambre à air

tirerepair-products.fr

Mèches de réparation Tubeless / Cordes de réparation des pneus sans chambre à air / Mèches de réparation des pneus sans chambre à air

tirerepair-products.fr