Variateur de fréquence moyenne tension dans pompe de condenseur de la centrale de Luanhe

Variateur de fréquence moyenne tension dans la centrale de Huayingshan

2010-1-4 10:51:13

Préface:

De 1950 à 1970, pour des équipements auxiliaires comme des ventilateurs de soufflage, ventilateurs aspirants et pompes, leur puissance de sortie ne pouvait varier avec la variation de charge. Dans les années 80, la technologie de variateur de fréquence a été grandement utilisée dans la génération de puissance, l’acier, l’eau et le ciment. Pour les anciennes centrales énergétiques, la consommation de puissance interne compte pour 10% de sa génération totale. Le ventilateur de soufflage compte pour 10% de la consommation. Le ventilateur aspirant compte pour 15% et la pompe pour 20%.

But for new plants with variable frequency technology, itself power consumption is only 6%. So lots of power plants take energy saving to schedule and start to seek method of energy saving by improving technology.

1. VFD application in Huayingshan Power Plant

Two sets of 100MW machinery unit started to run in 1980 and 1982. Two 780kW FD fans and two 800kW ID fans were equipped with boiler. Machinery peak-adjusting and two shifts operation accounted for 60% of total work time in recent years. ID fans and FD fans run in throttle mode in long term. In 2001, plant made reconstruction for two 100 MW machinery units with Leader Harvest VFD.

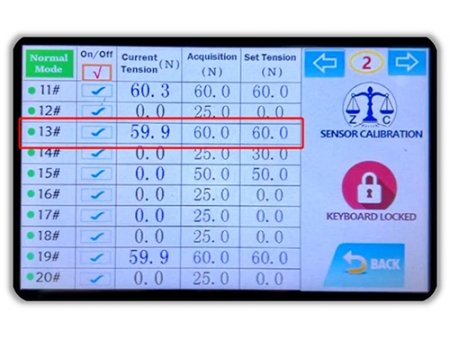

2. Operation and test

After reconstruction, static debugging, idle load commissiong, commissioning with load meet design requirements. Sichuan Power Test Institute made appraisal test for VFD in each work situations. The test items and results are:

(1) power factor test: power factors of ID fans and FD fans are 0.97~0.99.

(2)efficiency test: efficiencies of 8 sets of VFDs are 97%~98%.

(3)harmonic test: THD of 10kV power grid is 1.48%~1.84%,which meets requirement of less than 4%. THD of 110KV, 220KV power grid is 1.02%~1.42%,which meets requirement of less than 2%.

(4)start-up current comparison: in variable frequency mode, start-up current is small. Current rises smoothly; in direct on line state: start-up current is 6~7 times of rated current. Impact current is big and threats safety and motor lifetime.

(5)frequency range and precision test: frequency adjusting range is 0~50Hz. Static debugging precision is 0.01%~0.02%.

(6)energy saving test: measure energy saving rate of ID fan and FD fan in different loads of 50MW, 60MW, 70MW, 80MW, 90MW, 100MW ,110MW, they are 62.2%, 52.8%, 54.5%, 47.9%, 43.4%, 42.7%. Average energy saving rate is 52%.

3. Direct benefit analysis

According to above calculation results, in the case of annual work time of one unit is 5500 hours, average energy saving rate is 51.25%. Annual energy saving =fan capacity×work time×energy saving rate=(2×800kw+2×780kw)51.25%×5500h=8907250kwh. Cost =annual energy saving ×price=8907250kwh×0.25yuan/kwh=2226812 yuan. Annual coal saved=power saved×coal consumption=8907250kwh×0.421kg/kwh=3749952kg. Annual coal cost saved=coal saved×price=3749.952t×230yuan/t=862489 yuan. We see the benefit is very considerable.

4. Indirect benefit

In variable frequency state, small start-up current causes little impact to motor, cable and switch, which heightens health level and reduces maintenance cost. This cost is nearly 500000~1000000yuan. So economy benefit =2226812 862489 500000=3589301 yuan. The VFD reconstruction cost is 5 million yuan. It can recover in 2 years.

5. Influence on equipments

According to VFD principal, torque M is directly proportional to square of speed n. After reconstruction, low start frequency, low speed, small and smooth current realize soft start. It avoids big current and torque impact on motor, cable and switch. Meanwhile, fans run in low load(60~100MW)in long term. Motor frequency is usually in 30~47Hz. It prolongs motor lifetime, lightens shaft wear and tear, heightens system safety.

6. Concluding remarks

With increasing competition, how to reduce generation cost and heighten competitive power is an important issue for power plant. Variable frequency technology on auxiliary equipments, such as fan and pump, not only realizes energy saving, but also enhances system safety. So, VFD will have a widely application field in power plants.

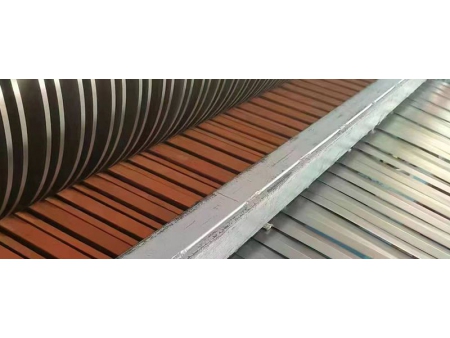

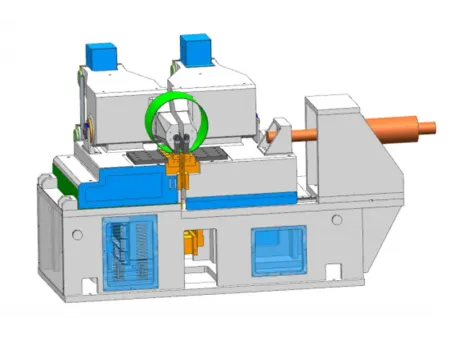

Machine à souder bout à bout / Machine de soudage bout à bout / Machine à souder par rapprochement

steelwheelmachines.fr

Machine à souder bout à bout / Machine de soudage bout à bout / Machine à souder par rapprochement

steelwheelmachines.fr