Variateur de fréquence moyenne tension dans la centrale de Yunfu

Variateur de fréquence moyenne tension dans la centrale de Yunfu

2010-1-4 15:25:47

Résumé : cette page vous présente l’application du variateur de fréquence VFD Harsvert dans la centrale de Yunfu, établi une comparaison en matière d’économie d’énergie et explique les perspectives d’application du variateur de fréquence VFD.

Mots clés : analyse d’application, multi niveau, variateur de fréquence moyenne tension (MV VFD)

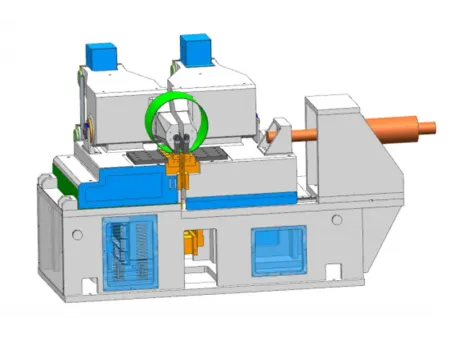

There are 4 sets of generators in power plant. Capacity of 1#, 2# units is 125MW. Capacity of 3#, 4# units is 135MW. Before reconstruction, 1# and 2# FD fans adopted damper adjusting, which caused much energy wasted. In order to save energy and improve adjustment quality, we finally chose variable frequency technology after long term discussion. Variable frequency technology is advanced and drive is installed easily. It only connects between MV breaker and motor, without modification for motor and load. In October 2006, we installed two HARSVERT-A06/130 VFDs in A, B sides 1#FD fan. VFD realizes stepless adjustment, wide adjustment range, high adjustment precision and high efficiency, soft start. VFD saves energy and reduces maintenance.

1. Reconstruction scheme

Motor parameters:

Model :Y500-4-6

Rated current :118.8A

Rated power: 1000kW

rated frequency: 50Hz

rated voltage: 6kV

rated speed: 990r/min

Bypass cabinet is designed to keep system reliability. When VFD is broken, motor is switched to direct on line manually. Bypass circuit is composed of three isolators. QS2 and QS3 are double throw isloators and they are interlocked. In variable frequency state, QS1 and QS2 close, QS3 opens; in direct on line state, QS1 and QS2 open, QS3 closes.

VFD link locks with MV breaker. In case of VFD fault, MV breaker trips off. In direct on line state, VFD cancels signal of breaker trip-off. Motor starts/stops by breaker normally.

S7-200PLC communicates with DCS. Start/stop, frequency adjustment are controlled by DCS. Meanwhile, VFD status feeds back to DCS.

2. Energy saving effect

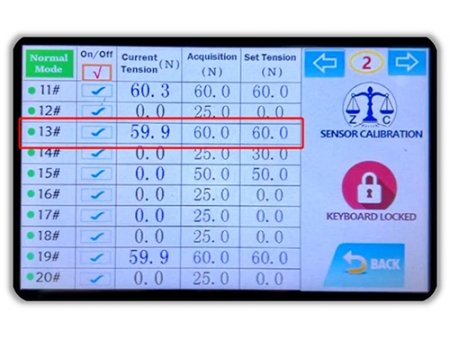

(1)VFD parameter

Model | HARSVERT- A06/130 | Input vlotage | 6kV |

Rated current | 130A | Rated power | 1000kW |

(2)motor parameter

Rated power | 1000kW | Rated voltage | 6kV |

Rated speed | 990rpn | Rated current | 118.8A |

(3)Calculation

For fan and pump: Q∝n ,H∝n2,P∝n3

n---speed;

Q---flow;

H---pressure;

P—shaft power

When motor speed decreases to 80% of rated speed, input power of system (VFD motor) decreases to 51% of that in rated speed. Thus, energy saving effect is more obvious when speed is low.

Make comparison in same working conditions:

Load | VFD before | VFD after | Energy saving rate |

125MW | 70A | 48A | 25% |

100MW | 55A | 29A | 40% |

The reconstruction cost can be recovered within 18 months.

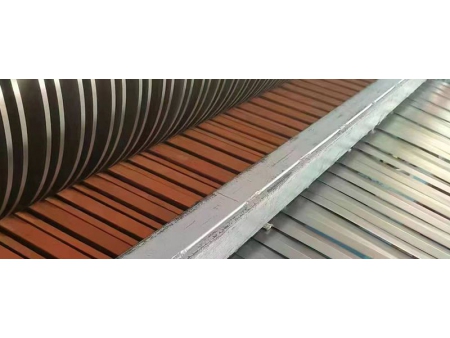

4. Air-water cooling system

The site is very hot in summer, so we installed air-water cooling system to ensure reliability.

Hot air from VFD enters cooling device through air channel. There is 33℃ cooling water tube which makes heat exchange with hot air. Heat is taken away by circulating cooling water. Air from cooling device is cold, which keeps inside temperature less than 40℃.

Cooling device

2 sets of cooling devices are equipped with VFD. Single device fault causes little influence. From practical application, inside temperature keeps about 30℃.

By calculating, cost of air-water cooling system is 50% of air conditioner cost.

Cooling device layout

5. Concluding remarks

VFD saves much energy, especially in low load. VFD realizes soft start, prolongs motor lifetime, eliminates surge, reduces wear and tear.

2 VFDs have been running stably since they put into service. The reconstruction is very successful.