Variateur de fréquence moyenne tension dans la centrale d’extraction d’aluminium de Pangang

Variateur de fréquence moyenne tension dans la centrale d’extraction d’aluminium de Pangang

2010-1-6 16:12:14

Résumé : cette page analyse l’application du variateur de fréquence dans le ventilateur de dépoussiérage de la centrale d’extraction d’aluminium en matière d’économie d’énergie, d’efficience et de protection environnementale.

Mots clés : variateur de fréquence haute tension VFD, raffinerie métallurgique pour extraction d’aluminium, IGBT, PWM.

I. Preface

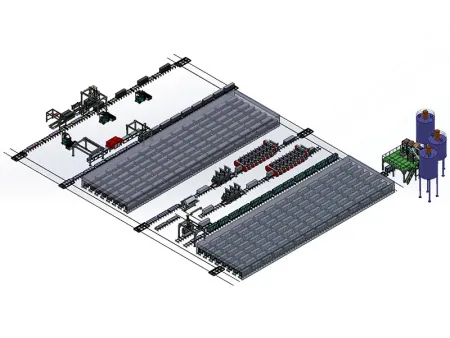

In recent years, Pangang Alum Extracting Steel Refining Plant built 2 sets of converters and dusting systems. It has a high requirement for fan operation. So we adopt technology of high voltage variable frequency drive, including Leader&Harvest, Rockwell, Robicon, Dongfan Electric and Alstom. VFDs are HARSVERT-A(4 sets), DHVECTOL-DI03000/06B(1 set), Power Flex7000(3 sets ), NBH(1 set), ALSPA MD2000(2 sets). There into, Leader&Harvest products apply most widely. They are mainly used to control SA fan of 6#, 7# converter, and PA fan of 4#, 5# converter.

II. Bypass circuit

Bypass cabinet is used to switch motor to direct on line when VFD is broken to ensure production continuity. The steel plant adopts modes of “one drive one” and auto bypass cabinet.

III. Comparison between HARSVERT-A VFD and current source VFD

HARSVERT-A VFD | Current source VFD |

High power factor | Low power factor, with power |

Without pollution for grid | There is pollution for grid, harmonic |

Applicable to common motor | Not applicable to common motor |

Non-stop when control power faults | Stop immediately when control power faults |

“one drive several” is available | “one drive several” is unavailable |

Can not operate in four quadrant | Can operate in four quadrant, |

Cell-cascade, high reliability | With problem of components in |

Interface is easy-operation | Interface is easy-operation but unstable |

Software is broken sometimes and | Hardware is broken sometimes and |

Solution of fault can be mastered | Solution is not mastered easily |

IV. Advantages of HARSVERT-A VFD

1. Energy saving

Take 4# and 5# converters as example: converter capacity is 120t, average iron water input is 120t, max iron input is 140t, max gas flow is 60000Nm3/h, blowing time is 10min, refining period is 20min, dust in gas is 80g/Nm3--120g/Nm3, fan pressure is 19000Pa, rated speed of fan is 1480rpm, motor voltage is 6kV, motor power is 1400kW. In converter refining technics drawing, we can see:

A~B: add waste iron, 2min

B~C: fan acceleration, 1min

C~D: blowing&refining, 10min

D: fan begins to decelerate

D~E: measure temperature and sample, 1min

E~F: output iron, 5min

F~G: discharge draff, 1min

The refining period is 20min. VFD runs in high speed 35Hz in C~D, and runs in low speed 18Hz in other time ranges. In original operation, fan run in 50Hz all the time during refining period. For 4# and 5# converter, monthly power consumption of PA fan is 1680000kW·h. This value is reduced to 1050000 kW·h by VFD. Power price is 0.55yuan/kW.h, monthly cost saved is 346000yuan (USD 50882).

2. Benefits

After using VFD, fan runs in low frequency and small current according to refining technics. In addition, soft start avoids big current impact on grid and motor, reduces wear and tear on bearing and impeller, reduces times of changing rotor. There is excessive 5 hours for refining every month. Each furnace steel:120t; refining period: 20 min; steel profit: 200yuan/t

Additional steel produced every month:

5×60÷20=15(furnace)

120×15=1800t

1800×200=360000yuan (USD52941 )

V. Concluding remarks

Leader&Harvest VFDs have been running stably for several months in steel plant. They save lots of energy and heighten work ability of dusting fan, improve environment, heighten efficiency and make contribution for safety and environmental protection. So high voltage VFD is indispensable in dustying system and it is worthy to promote in the field.