Variateur de fréquence moyenne tension dans la centrale thermique de Liaocheng

Variateur de fréquence moyenne tension dans la centrale thermique de Liaocheng

2009-12-27 12:35:31

Résumé : cette page analyse les caractères technologiques du variateur de fréquence VFD et ses effets d’économie d’énergie. Combinant les caractères techniques de la pompe de condensation, elle réalise une estimation d’économie d’énergie.

Mots clés : variateur de fréquence moyenne tension VFD, pompe à eau condensée, économie d’énergie.

I.Preface

Liaocheng Thermal Power Plant locates in Liaocheng city which is a recent emerging industry city in westen of Shandong province. The plant has 8 machines with capacity of 1280MW. In order to abide by state policy of energy saving and emission reduction, plant planned to make reconstruction with VFD for condensing pumps of two 300MW machines.

Equipment | Motor model | Power | Rated voltage | Rated current | Rated speed | Pump model | Flow | Lift |

Condensing pump | YLKK500-4 | 900kW | 6kV | 103.3A | 1480rpm | NLT350-400*6 | 847m3/h | 288m |

II. Variable frequency system

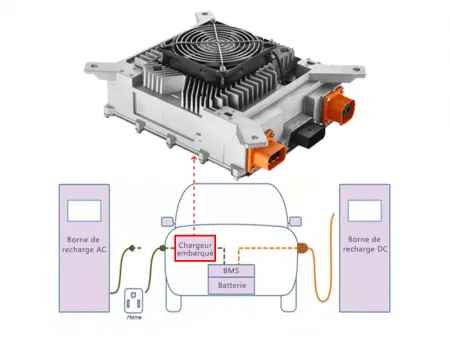

The system is composed of three medium voltage isolators QS1, QS2 and QS3. QS2 and QS3 are mechanical interlock. They can not close simultaneously. When motor runs in variable frequency, QS1 and QS2 close, QS3 opens. When motor runs in direct on line, QS3 closes, QS1 and QS2 open.

Advantages: There are obvious points of power off for VFD maintaince, which can ensure personnel safety. Bypass circuit can switch load to direct on line. Price is low.

III. Operation state of condensing pump

After condensating, vapour which does work in low pressure cylinder of steam turbine is collected in condensing water tank. Condensing pump delivers condensing water to deaerator in time to maintain level balance. So continuous and stable operation of condensing pump is one of important factors which ensure generator safety and economized production.

Before using medium voltage VFD, water level of condenser is adjusted by changing outlet valve opening. Linearity is inferior and lots of energy wastes on valve. In the mean time, frequent operation on valve leads to valve reliablity down, affecting stable operation of system.

After using medium voltage VFD, no need to adjust outlet valve. Valve opens at a large scope. Adjusting VFD output frequency changes motor speed, reaching purpose of outlet flow adjustment. Following is condensing water system:

IV. Benefit analysis

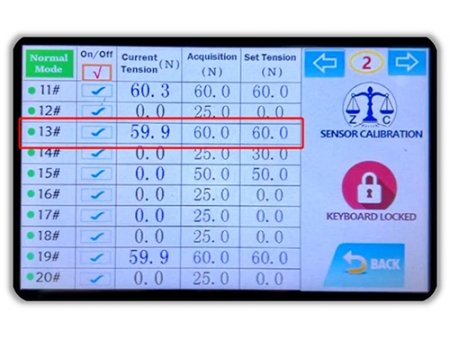

1. Power saving is evident. Following is operation data. Compare before and after currents , we find current lowers greatly.

Load | 150 | 160 | 170 | 180 | 190 | 200 | 210 | 220 | 230 | 240 | 250 | 260 | 270 | 280 | 290 | 300 |

Pump current | 82 | 82 | 81 | 82 | 82 | 82 | 84 | 84 | 85 | 86 | 87 | 88 | 88 | 90 | 91 | 93 |

Pump current | 19 | 19 | 24 | 24 | 25 | 31 | 32 | 29 | 32 | 38 | 40 | 42 | 50 | 52 | 55 | 60 |

Current down A | 63 | 63 | 57 | 58 | 57 | 51 | 52 | 55 | 53 | 48 | 47 | 46 | 38 | 38 | 36 | 33 |

2. Following is statistic of power consumption in a month.

Generator | Power generating kW·h | Power consumption of pump kW·h | Power consumption/power generating | Power saved kW·h |

#7 line frequency | 191166000 | 646200 | 0.34% | |

#7 variable frequency | 193716000 | 411300 | 0.21% | 234900 |

V. Concluding

Through analyzing condensing water pump system of Liaocheng Thermal Power Plant, we think it is feasible to reconstruct with VFD for two pumps. Changing valve control to variable speed adjustment can reach purpose of lowering power consumption rate. VFD also brings benefits in terms of safety, reliability and equipment maintaince.

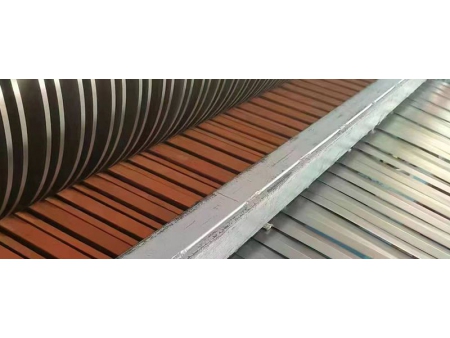

Mèches de réparation Tubeless / Cordes de réparation des pneus sans chambre à air / Mèches de réparation des pneus sans chambre à air

tirerepair-products.fr

Mèches de réparation Tubeless / Cordes de réparation des pneus sans chambre à air / Mèches de réparation des pneus sans chambre à air

tirerepair-products.fr