Potentiel de développement et application du variateur de fréquence moyenne tension

Potentiel de développement et application du variateur de fréquence moyenne tension

2010-1-4 14:43:08

Résumé : sur cette page vous sont présentées la faisabilité et les règles de choix de l’application du variateur de fréquence moyenne tension VFD en centrale. Quelques exemples d’application vous sont donnés et les perspectives de cette technologie vous sont présentées.

Mots clés : variateur de tension moyenne fréquence (MV VFD)

I.Feasibility of VFD technology in thermal power lant

Power generation plant is manufacturer of power as well as consumer of power. In structures of Chinese power generation plants, thermal power plants account for 70%. For general coal-fired generator units, plant itself consumes 4%~7% of its generating power and auxiliary equipments, such as big capacity fans and pumps, account for 80%. Coal consumption and power consumption rate of plant have been important index for power plant and they have a direct relationship with economic benefit and company competitive power. Energy saving effect resulted from variable frequency adjustment on auxiliary equipments such as fan and pump can reduce power consuming cost and power generating cost for power plant. So it is very urgent to choose appropriate MV VFD.

With fast development of power grid, increasing of machinery capacity and peak valley of load, requirement for peak adjustment ability is higher and higher. Operation state of units must vary with load changing. Even for unit with base load, capacities of auxiliary equipments and motor are far more than the actual need, which results in “ big horse pulls small carriage”. So it requires that auxiliary equipments can work in variable frequency state to meet actual need.

Some relevant statistics show that about 15% faults of motor are caused by big starting current and big electromagnetic force on coil. Start directly also affects stator windings terminal weld-off, rotor squirrel cage strip-break and many other faults of auxiliary equipments. Frequency start-up resulted from peak adjustment operation causes more faults of equipments, shorts maintenance period and lifetime of equipments, increases maintenance cost and labour cost, results in great economic loss.

It is obvious that large auxiliary machinery designed as full load is not applicable to new operation mode. Original adjustment method has problems of source serious waste and bad adjustment quality. Frequent start/stop impacts auxiliary equipments, motor and power grid, which threats safety of units. Medium voltage vairable frequency adjustment technology can meet requirement of auxiliary equipments through soft start. It provides a safe and feasible operation mode for large auxiliary equipments in power plant.

As a new electrical technology developing quickly in 1990s, medium voltage variable frequency adjustment technology mainly used in MV motor. Variable frequency adjustment technology is better than any other in speed adjustment mode. It is well known as its remarkable energy saving, high efficiency, high precision, wide adjustment range, perfect electric protection and auto communication. It is also safe, reliable, easy installation&maintenance, which makes it first preferred drive for power plant in energy saving field.

II. Choose MV VFD for power plant

Power plant should consider reliability, economy, applicability and environment protection:

1. Reliability

(1) Reliability of components: LV is better than MV. Mature product is better than the immature. For the same component, the better can be chosen according to the brand and class.

(2) Reliability of main circuit structure: for the requirement of reducing waste of transmitting power, most big capacity motors are medium voltage motor. Voltage class is most 6kV and 10kV.

There are several modes for VFD to output medium voltage. For high-high mode, the reliability of power cells seriers-connecting is better than direct-connecting of components. Medium-low mode or medium-low-medium mode is only temporary solution in development and they should disappear in market. Some experts believe motors of 1.7 kV, 2.3 kV, 3.3 kV, 4.16 kV should be researched or change connecting mode of motor coil and add a transformer ahead of VFD to match VFD, which acts in a procrustean way.

(3) Reliability during operation: power plant has following requirements for VFD to ensure generator units safefy: continue derating operation with several cells broken; can be transferred to direct on line state when VFD is broken; VFD does not stop during instant power-fault; equip UPS for controller; power source of 380V fan is supplied by VFD.

2. Economy

Economy can be discussed from price, spare cost, maintenance cost and product benefit. After-sale service is good and high effective because of self-research&manufacture, which reduces maintenance cost and protects user’s investment to meet power plant requirement at maximum.

Meanwhile, MV VFD technology characteristics can also influence economy. For VFD with harmonic filter or power factor compensator, its efficiency and reliability must be low and operation time is short; for VFD equipped special motor, no capability of interchaning of motor; for VFD without cell-bypass function or no function of bypass to direct on line, MTBF is reduced greatly. These result in low efficiency of whole units.

3. Applicability

MV VFD should adapt power grid fluctuation including bus low voltage and short time bus voltage failure. VFD also implements soft-start, soft-brake and intellectual speed-adjusting during frequent start/stop and high/low load changing.

Take example of HARSVERT-A series VFD: it is cell-cascaded multi-level PWM voltage source type, can meet user requirement.

Outside applicability of Harsvert VFD:

Direct medium voltage input and medium voltage output, without harmonic filter or power factor compensator;

VFD can continue running with 30% voltage drop;

VFD does not stop but derates to run automatically when medium voltage is low. VFD recovers original speed when voltage is normal;

VFD does not stop within 3s when medium voltage faults, which can meet demand of no stop during switching bus. But for other same kind drive, this value is only 100 ms.

Operation and maintenance

There are local start/stop and remote start/stop, function set, parameter set, fault inquiry, operation record on WINDOWS interface.

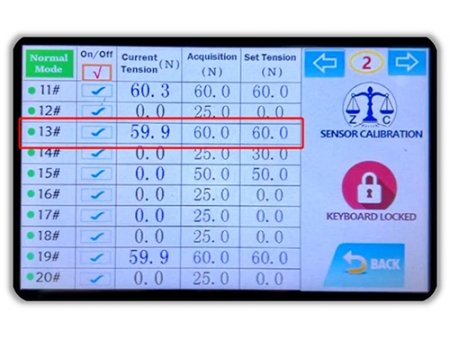

Set VFD parameters by colourful LED touch-screen. Output operation data table can be printed out. HMI can display voltage/ current waveform, frequency, speed and motor status at any time.

Good ability in detecting and indicating: operation status of every part of VFD can be detected. Integrated fault monitor circuit, accurate fault orientation, fault position and type showing in HMI make fault points clear at a glance. Easy replacement of broken cell reduces MTTR and can be operated by general personnel.

VFD can be controlled in site or remote area. User can choose local control or remote control. With remote control function, user can control VFD by network. It is easy for user to master VFD actual operation status in remote and it also benefits for remote detection and maintenance, so faults can be solved in time.

Corporation with units

VFD can be connected to DCS of power plant

VFD accepts and outputs standard signals of 0~10V/4~20mA

VFD realizes data exchange and interlock control. VFD can provide alarm signal and keep original output frequency same when analogue signal faults or short circuit.

Inside PLC can change control logic easily, which meets site changeable need; there is also international external port. VFD can realize open loop control and close loop control.

User special requirement

Control power of VFD accepts AC 220V and DC 220V. With inside UPS, VFD can continue running and alarm when control power is broken.

LV power source can be supplied by transformer secondary of VFD, which enhances reliability.

User can choose manual or auto bypass cabinet. Motor will be switched to direct on line when VFD is broken through bypass cabinet.

4. Environment protection

During MV VFD operation in power plant, the biggest problem is harmonic pollution. The active way is that adopting multi-level PWM technology and improving circuit topology structure make electric device not bring harmonic and reactive power. Leader Harvest VFD is designed according to this idea and it has got inspection certificate from authority institute.

III. MV VFD application in power plant

4 sets of 800kW/6kV Leader Harvest VFD for 4# ID fan in Sichuan Huayingshan Power Plant finished acceptance inspection in Nov. 2001.

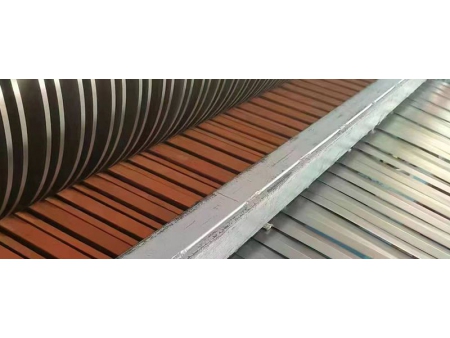

Rebuild instruction: install VFDs for 4 motors respectively at both side of ID fan. Use original motors to realize variable frequency adjustment and keep original equipment same as before. Keep air channel of original ID fan and FD fan. Install VFD bypass cabinets. Motor works in direct on line when VFD is broken and air flow is controlled by damper.

Besides local control, personnel can operate and monitor VFDs in DCS of central control room.

VFDs achieve following effects:

1. Satisfy requirement of speed-adjusting technology and realize automatization of generator units.

Stepless speed adjustment in wide range not only satisfies need of peak adjustment, but also realizes motor soft-start, soft-brake and intellectual speed adjustment by connecting to DCS of power plant. VFD adjusts motor frequency and speed to control air flow according to burning status, achieving close loop adjustment. VFD improves production efficiency and automatization, enhances work quality and manufacture environment.

2. Energy saving

Energy saving rate is shown in following table.

Load (MW) | Work mode | Power ((kW) | Total power (kW) | Power saved (kW) | Energysaving rate(%) | |||

A ID fan | B ID fan | A FD fan | B FD fan | |||||

50 | Variable frequency | 243.5 | 202.5 | 113.4 | 156.6 | 707.0 | 1162.3 | 62.2 |

Direct on line | 670.5 | 513.0 | 374.4 | 311.4 | 1869.3 | |||

60 | Variable frequency | 270.0 | 227.7 | 203.4 | 117.0 | 818.5 | 1076 | 56.8 |

Direct on line | 679.5 | 513.0 | 390.6 | 311.4 | 1894.5 | |||

70 | Variable frequency | 279 | 243.0 | 140.4 | 225.0 | 887.4 | 1062 | 54.5 |

Direct on line | 547.2 | 667.8 | 387.0 | 347.4 | 1949.4 | |||

80 | Variable frequency | 396 | 322.2 | 261.0 | 171.0 | 1150. | 1059.3 | 47.9 |

Direct on line | 681.3 | 696.6 | 414.0 | 417.6 | 2209.5 | |||

90 | Variable frequency | 423.0 | 392.4 | 297.0 | 180.0 | 1292.4 | 992.7 | 43.4 |

Direct on line | 679.5 | 720.0 | 446.4 | 439.2 | 2285.1 | |||

100 | Variable frequency | 450.0 | 401.4 | 315.0 | 183.6 | 1356 | 1006.2 | 42.7 |

Direct on line | 739.8 | 730.8 | 446.6 | 441.0 | 2356.2 | |||

Energy saving rate is 62.2%~42.7% when load is 50%~100% of rated load. Average energy saving rate is 51.25%.

3. Prolong equipment lifetime, and save maintenance cost and time

After rebuilding for #4 units with VFD, motor realizes soft-start. Impact on motor, fan, damper and MV switch is greatly reduced. Low speed operation reduces fan vibration and wear and tear of shaft a lot, extends equipment lifetime, saves maintenance cost and time.

III. Prospective development of MV VFD

Adjusting speed of auxiliary equipments such as fan and pump by variable frequency technology makes each parameter at the best state, which improves operation, enhances efficiency and saves power, water and coal, reduces production cost, brings lots of benefits for power plant. Meanwhile, VFD cooperates with control system of units, which can improve automatization level, save labour, enhance management level of whole system.

There are two aspects for VFD development in power plant. One is VFD itself development; the other is how to cooperate with progress of plant production technology and automatization.

For VFD itself development: development in big capacity and small dimension, modularization, voltage withstand and hardware universal are research goals in short time.

For application in power plant: manufacturer should improve VFD self-detection function; restore VFD fault quickly; solve problem of damper and valve quick response; digital connection to central system and so on. Furthermore, anti-dirt, heat, anti-disturbance and reliability should be researched and explored for a better mode.

IV. Conclusion

MV VFD provides a feasible operation mode for auxiliary equipments in power plant. Its excellent performance and energy saving effect make its widely application in power plant. User should consider reliability, economy factor, applicability and environment protection when choose a VFD. VFD is an important way to reduce cost and enhance competitive power for plant.

Vanne papillon avec actionneur électrique / Vanne papillon à commande électrique / Vanne papillon à actionnement électrique

custom-casting.fr

Vanne papillon avec actionneur électrique / Vanne papillon à commande électrique / Vanne papillon à actionnement électrique

custom-casting.fr