Variateur de fréquence moyenne tension dans haut-fourneau à soufflage

Variateur de fréquence moyenne tension dans haut-fourneau à soufflage

2010-1-6 16:11:24

Le 2nd département de Fushun Xinfugang Steel Refining Company est doté de trois ensembles de convertisseur de soufflage d’oxygène au dessus du bain de 15t (capacité désormais étendue jusqu’à 20t). En 2001, la production annuelle était de 710 000t.

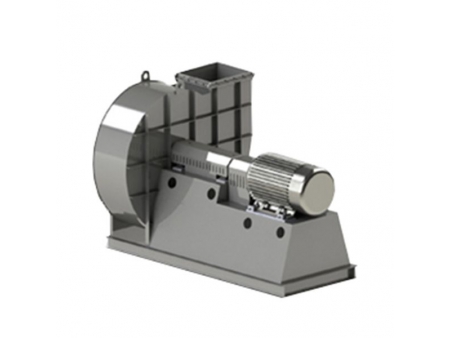

Comme les convertisseurs arrêtent de souffler périodiquement de l’énergie, ils nécessitent que les ventilateurs tournent à vitesse variable durant la période de raffinage afin de répondre aux besoins d’économie en énergie et de protection environnementale. Le mode d’ajustement original de la vitesse est un couplage hydraulique. Haute vitesse de 2700r/min et basse vitesse de 800r/min. Il y a les problèmes suivants en raison de la limitation du couplage hydraulique.

1. Adjustment range is 30%~90%, speed is unstable. Furthermore, low speed 800r/min is still high, which causes energy wasting. In high speed, there is slippage and smoke rising from converter mouth.

2. After 10 years of operation, hydraulic coupling is serious aging. It needs to change bearing frequently, which leads to stop converter. That can not meet requirement of continuous production.

3. Motor efficiency is low, particular in low speed.

4. Low adjustment precision, inferior linearity, slow response.

5. Big start current affects power grid stability.

6. Motor can not switch to direct on line when hydraulic coupling is broken. Machine must stop to repair.

7. Oil leakage pollutes environment serioulsy and corrupts floor heavily.

Thereby, it is urgent to reform hydraulic coupling.

At the end of 2001, the company began to expand the plant. In order to heighten fan efficiency and solve problems of hydraulic coupling, company decided to reform with VFD. Requirements of VFD is following:

a. VFD can run for long term without fault with high reliability.

b. Motor can switch to direct on line when VFD is broken.

c. Adjustment range is wide and efficiency is high. VFD should have logic control ability.

d. VFD can accelerate/decelate automatically according to oxygen blowing period.

e. VFD has skip set for resonance points, which can avoid resonance points during operation and prevent fan from surging.

After investigation and comparison, the steel company purchased a 6KV/630KW VFD from Leader&Harvest at the end of 2001. The VFD put into service on 14 th March, 2002. Compared with original hydraulic coupling, VFD has following advantages:

a. Operation is stable, safe and reliable. For hydraulic coupling control mode, bearing has to be changed every 40 days. Changing bearing needs to stop for half a day, which brings much economic loss. For HARSVERT-A VFD, it is free maintaince and only needs to change filter and no need to stop, which ensures production continuity.

b. Energy saving effect is obvious and power consumption is lowered greatly.

c. Soft start and soft stop function. Sine current supplied by VFD reduces motor fault. VFD sets skip resonance points to avoid operation on resonance points for long time. It reduces wear and tear of bearing, prolongs equipment lifetime and heightens utilization factor of fan.

d. VFD has completed protection. Compared with relay protection, VFD protection is more sensitive and completed. During commissioning in site, VFD protected and reported over current of motor. After inspection, we found one phase cable terminal was cracked. lack phase caused over current. we repaired in time and accident was avoided.

e. Communication meets production need. Imbeded PLC makes signal input flexible. Converter provides a pair of high speed nodes and a pair of low speed nodes. VFD runs in high speed or low speed automatically according to nodes state. Gas flow and temperature signals which are in instrument cabinet are connected to VFD. Instrument cabinet is dismantled and installation space is saved greatly. VFD has speed meter, so original speed meter is canceled. VFD can indicate motor speed in site.

f. Adaptive ability for grid vibration is strong. Grid voltage reaches 6.9kV sometimes, but VFD still works normally.

Because Leader&Harvest VFD has above advantages, Xinfugang Steel Refining Company decided to purchase again for 2# and 3# converter. 2# and 3# VFDs put into service and passed the inspection on 30 th July, 2002.