Analyse de moteur à économie d'énergie dans les cimenteries

2009-12-15 14:28:12

Résumé : à présent, la compétition dans l’industrie du ciment est intensive. Le facteur clé en est le coût de production. Comme la consommation des moteurs compte pour 30% du coût total, l’économie d’énergie pour le moteur est très importante.

Mots clés : moteur, variateur de fréquence VFD, économie d’énergie.

I.Speed adjustment for motor

Conventional speed adjustment has several modes. They are thyristor cascade control, DC adjustment, electric magnet sliding differential speed control, hydraulic coupling control, pole-changing control. They have disadvantages of low driving efficiency, difficult maintaince. But variable frequency control is stable and reliable with high precision and wide adjustment range.

II. Energy saving principle of variable frequency control

In cement plants, some big power equipments run in low load in most time during production. Air/water flow demand is controlled by adjustment valve opening or damper. Disadvantages of this adjustment mode is:

1. Speed of motor and fan/pump is high. Power wasting is serious.

2. Automatization level is low. Precision of manual adjustment is low.

3. Motor starts directly. Big start current brings impact on power grid. Power factor is low.

4. Mechanical impact is big during starting. Lifetime of equipments is short.

5. Noise is big. Fine dust pollution is serious.

Main equipments of cement plant are: material grindering fan, kiln end waste gas processing fan, Roots blower, cement grindering fan, coal grindering fan, cooling fan, powder concentrator, circulating pum and feeding pump. Basic principle of variable frequency control is that motor speed is in direct rate to input frequency: n =60 f(1-s)/p(n: speed; f: input frequency; s: slip ratio; p: number of pole pairs). Changing frequency reaches purpose of variable speed. According to fluid mechanics: for load such as fan/pump, there are following relations between speed n, flow Q, pressure H, shaft power P: Q∝n,H∝n2,P∝n3. Namely, flow is in direct rate to speed; pressure is in direct rate to square of speed; shaft power is in direct rate to cube of speed. Please see following figure.

n1 stands for curve of motor operation in rated speed; n2 stands for curve of motor decelerating at speed n2; R1 stands for fan/pump resistance curve in least resistance; R2 stands for fan/pump resistance curve at some group data.

When fan/pump works at curve R1, operation point is A. Its pressure is respective Q1、H1. At the moment, fan/pump power demand is in direct rate to product of H1 and Q1, corresponding to area of AH1OQ1. Because technics requires flow to reduce to Q2,by increasing pipe resistance makes work point of fan/pump move to B of R2. Pressure increases to H2. At the moment, fan/pump power demand is in direct rate to product of H2 and Q2, corresponding to BH2OQ2 area. Obviously, fan/pump power demand increases. This adjustment is easy, but power consumption is much, not advantageous to energy saving. In variable frequency control, fan speed reduces from n1 to n2, at the moment, work point moves from A to C. Flow is still Q2. Flow reduces from H1 to H3, at the moment, fan power demand is in direct rate to product of H3 and Q2, corresponding to CH3OQ2 area. From the figure, power reduced is considerable.

That is to say, when fan/speed speed reduces 10%, power consumption of motor reduces 27.1%. So energy saving of variable frequency control is obvious.

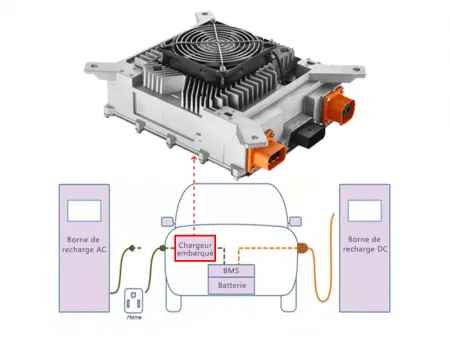

III. VFD application

1. VFD application on air compressor

Close loop control system composed by VFD and pressure control reduces pressure 1.5% vibration, noise and impact. It reduces maintaince labour, ensures stable operation for long term and prolongs equipments lifetime. In VFD control, air compressor can start randomly at any pressure, which breaks the law of prohibition start with pressure. Start current lowers greatly. By utilizing VFD, energy saving rate is 20%.

2. VFD application on Roots fan

In power consuming on clinker burning, Roots fan accounts for 60%. With power price rising, power cost rate of production cost is more and more. Therefore, it is key to lower energy consumption of fan. VFD can change frequency of power source and implement stepless speed adjustment. Chongqing Diwei Cement Plant installed VFD on 132kW Roots fan. Its energy saving rate is 62.2%. Power consumption reduces to 5.55kW.h from 15.22kW.h. Henan Jiaozuo Cement Plant installed VFD on 55kW Roots fan of 10000t/d production line. Its energy saving rate is 73.2%. Daily consumption reduces to 162 kW.h from 606 kW.h, about 444kW.h is saved.

3.VFD application on centrifugal fan

Some cement plants use centrifugal fan to supply wind. Air flow is adjusted by valve opening. VFD also has great potential on energy saving. Because air flow of fan is in direct rate to speed, pressure is in direct rate to square of speed, power is in direct rate to cube of speed. Therefore, if flow lowers 20%, power will lower 50%. We must notice because of square relation between speed and pressure, when speed lowers 20%, pressure will lower 60%. So we should take account of relation of speed and pressure.

4. VFD application on unloader

If unloader uses sliding differential speed adjustment, its speed is usually controlled in 300~1000rpm. Replacing sliding differential motor by variable frequency control, energy saving rate can reach to 40%. Sliding differential speed adjustment is in low efficiency.

5. VFD application on powder concentrator

In Chongqing Diwei Cement Plant, power concentrator is drived by 75kW electric magnet motor. Its advantages is easy and low price. Its disadvantages is : big noise and impact, much energy waste, frequent fault of bearing. Silding differential instrument is installed near to motor. Faults of unable speed adjustment and speed reduction usually occur. Maintaince labour is much, affecting safety of whole system.

6.VFD application on water-preadding and ball-forming system

At present, technology of water-preadding and ball-forming is very common in cemnt plants. It has ideal effect on improving quality of ball-forming and bruning operation condition. Integrating with computer double routes regulator realizes water material rate auto trail and auto adjustment to reach constant pressure water supply. It adjusts in time and reduces worker labour greatly, meanwhile, it improves ball-forming quality, creats conditions for high quality and production.

7. VFD application on ball-forming system

Ball-forming is one of key processes which affect quality of clinker burning. Rate of water and clinker affect ball quality directly. VFD can adjust speed of preadding water pump by trailing material feeding, thereby implementing close loop control. Main purpose of VFD reform on this project is to heighten automatization level and production technics. Its energy saving effect is secondary.

8. VFD application on material homogenization feeding system

Feeding motor is driven by VFD to implement stepless speed adjustment. It can heighten homogenization effect.

9. VFD application on cyclone separator

System principle is that according to different labels of cement, adjust speed of classifier and powder concentrator to select cement product in different fineness. Old type of cyclone separator needs to adjust number and angle of blade to reach required fineness by comparison test. New type of cyclone separator has classifier and powder concentrator. Classifier speed is adjusted by sliding differential motor. Powder concentrator adjusts air flow by adjusting damper. The two systems all have disadvantages of complicated technics, inferior precision and serious waste. With VFD, no matter it is old type or new type, as long as adjusting motor speed to some value, required fineness can be separated. It saves energy, and implements continuous and automatic production, heightening work efficiency and reducing work labour.

For above problems, combining character of classifier load speed not beyond 600r/min, we refom electrical part with VFD. Before reform, when operation speed is 594r/min, input voltage 385V, input current 72A, power factor 0.82, so input power 40kW. After reform, when operation speed is 594r/min, input voltage 387V, input current 18A, power factor 0.92, so input power 11kW. There is no fault during a year operation. VFD ensures safe operation, reduces maintaince labour and cost greatly. Energy saving is considerable.

10. VFD application on unload system

In order to keep balance for adding material, supplying air and unload during burning, shaft kiln usually uses sliding differential motor as power of unload system. IP class of this kind of motor can not meet requirement. Furthermore, its power consumption is 20% more than series motor at the same output speed. And the difference is more during decelerating. Variable frequency control can solve above problem. Its adjustment performance is better than sliding differential motor. It saves energy, reduces maintaince cost. This kind of adjustment applies in many industries.

VFD also has function of soft start. It reduces start current and operation current, reduces load intensity during starting and running, prolongs equipments lifetime. In addition, VFD reform improves IP class of motor, reduces motor fault caused by inferior environment.

IV. Concluding remarks

VFD applications in cement plants are more than above sites, such as ball milling, unload rolling, feeding machine, cooling machine and all equipments which need speed adjustment.

Practise proves that VFD reform has obvious energy saving effect. It is an ideal speed adjustment mode. VFD heightens equipment efficiency, meets technics requirement, reduces maintaince labour and cost a lot. In addition, DC reactor inside VFD improves power factor, saving capacity of power grid.

In conclusion, variable frequency has following advantages:

a. Damper is cancled. Equipment fault lowers, energy saving is obvious.

b. Soft start prolongs equipments lifetime, avoids impact on power grid.

c. Motor runs in low speed, reducing noise.

e. Protections of overload, overvoltage, overcurrent, lowvoltage, lack-phase.

f. Heighten production and quality.