Application démarreur moyenne tension en place

Application démarreur moyenne tension en place

2010-1-6 10:19:06

I. Introduction au projet

Qinghai Zhongxinguoan Technology Developing Co., Ltd est un producteur de fertilisants et matériaux chimiques. Il se situe dans le centre du bassin de Chaidamu. L’énergie de production et à vivre est fournie par sa propre centrale. La capacité du réseau électrique est limitée et ne peut supporter de grands impacts. Le principe de la tour de séchage par pulvérisation est le suivant : l’air passe par le filtre et le chauffage, puis entre dans le dispositif de division de la tour de séchage et entre ensuite dans la chambre de séchage de manière uniforme, en hélice.

Passing filter via liquid channel, material liquid is delivered to centrifugal atomizer of dry tower. Material liquid is sprayed into very fine mist-state drops. It contacts with hot air. Water is evaporated quickly and material liquid is dryed into product. The product is discharged from dry tower underneath and cyclone separator. Waste gas is discharged by fan. Spray dry tower is equipped with four sets of high voltage suction fan. If start fan in full voltage, big start current and big impact torque accelerate ageing of cable and motor, as well as wear of impeller and bearing. Start-up impact may cause stop of whole power grid. Whereas above state, soft starter for high voltage fans is indispensable.

Motor parameters

Model | YKK500—4 | Power | 630kW |

Rated voltage | 10kV | Speed | 1489r/min |

Rated current | 45.2A | Power factor | 0.86 |

Fan parameters

Flow | 180000m3/h | Speed | 1450r/min |

Power | 630kW | ||

Manufacturer | Sichan Fan Plant | ||

II. Scheme and equipment

After comparing kinds of schemes, we decide to use Leader&Harvest scheme at last.

In order to reduce start current, big power motor needs starter. Common soft starter adopts mode of reducing voltage but not reducing frequency. It reduces start current, but torque is also reduced a lot, so its application is restricted. In addition, there is also big harmonic to power grid. Leader&Harvest product is soft starter of variable voltage variable frequency. Voltage and frequency rise from zero. Rate of voltage and frequency(V/f=C) keeps constant. Motor current is decided by load. Start torque can reach max torque of motor, so it is not restricted. Start time and start torque can be adjusted, so it is very convenient. The product can prolong lifetime of motor and mechanism, without impact on grid and without affection on other electrical equipments.

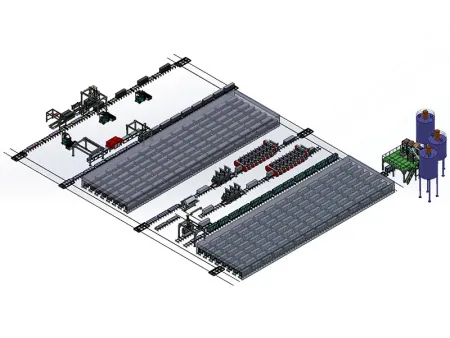

This project adopts scheme of “one drive four”, namely one VFD drives four motors. In plateau of 2800 altitude, soft starter connects to 10kV cable and makes motor soft start. Once motor frequency reaches line frequency, soft starter disaffiliates motor and stop running. Motor is switched to direct on line simultaneously.

Variable frequency soft starter is controlled by operation box. It implements soft start for each motor according to operation state. When motor speed accelerates from zero to rated speed, soft starter sends signal to operation box and operation box makes motor finish switch.

Soft starter adopts technology of modern SPWM. It starts up in the state of keeping constant magnetic flux. Soft starter adjusts motor voltage and frequency, makes motor start from zero to rated value according to expected curve. Motor starts up smoothly. That can lower requirement of power source and reduce affection on grid and motor. Soft starter has protection of overload, short circuit, overcurrent, low voltage, lack phase for motor

Main circuit:

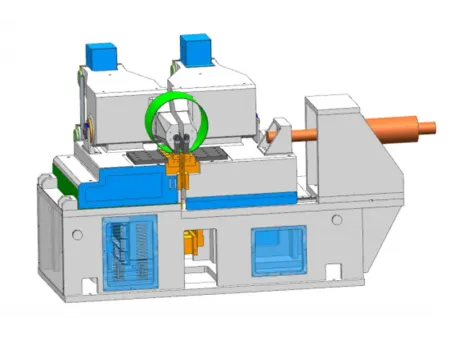

This is bypass scheme. It is composed of 8 contactors KM1~KM8 and 4 isloators QS1~QS4. KM1 and KM2 can not close together, KM3 and KM4 can not close together, KM5 and KM6 can not close together, KM7 and KM8 can not close together. KM2, KM4, KM6, KM8 can not close together and they interlock electrically.

Soft starter is HARSVERT-A10/050, rated capacity is 400kVA, max capacity is 790kVA.

III. Characteristic of soft starter

a High-high structure, cell-cascade PWM mode, 10kV output directly.

b 8 grade series connecting, 48 pulse input without harmonic.

c Soft starter can run during voltage 10%~-10% and derate to run during voltage -10%~-35%. That avoids damage on motor resulted from grid voltage down.

d Big power components contactless control in start-up process, motor accelerates smoothly, which protects motor and its connecting mechanism farthes.

IV. Operation effect

In order to implement ligh-load start, close air gate of fan in start-up process. In actual start process (0~50Hz), motor current does not change suddenly. It runs stably and current is less than rated current(45.2A) all the time. Soft starter starts each motor successfully, protects motor and fan effectively and ensures grid stability.

In contrast to common soft starter, variable frequency soft starter has following advantages:

a It does not need full load operation for long time. It only drives motor to line frequency. So we can take advantage of strong overload ability of dry transformer to reduce transformer capacity. This can save cost.

b Variable frequency soft start is more smooth, without current sudden change, no impact on motor and grid. Start-up time is in wide range.

c Completed protection, such as over voltage, low voltage, overload, over current, lack phase, over heat.

d High reliability and stability of components.

e Optical fiber connecting between high voltage and low voltage, with good separation and reliable triggering.

f Small volume and compact structure make it nice figure.

g HMI makes operation visual and easier.

V. Concluding remarks

Application of variable frequency soft starter exploits new field of Leader&Harvest product, makes wide variety of product.